Topics

Definition

Classification

Mechanism of lubrication

Properties

Solid lubricants

LUBRICANTS

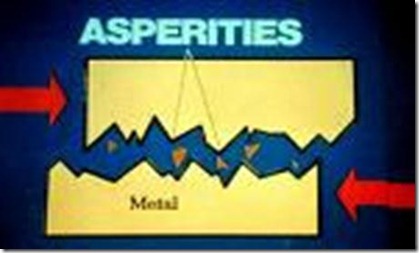

On viewing under an electron microscope, the surface of even a mirror polished metallic surface exhibits irregularity. The peaks are called asperities and the valleys are called pits

Scanning Electron Microscopic Picture of Mirror Polished Platinum Surface

Asperities and Valleys on two sliding surfaces

Types of Friction:

There are two types of friction (Static and Dynamic)

• Sliding Friction: Two flat Surfaces in motion

• Rolling Friction: At least one moving surface is spherical

Frictional Heat and Welded Joints

Ar= Real area of contact, junction, high stress, plastic deformation, adhesive bonding

B = Area filled with oxides, lubricant or air

Micro weld is the area where invisible welded joints are formed

N = Normal force

F = Frictional force

Definition

Substances introduced between moving surfaces in order to reduce friction and thus prevent welded joints and seizure, are called Lubricants

The process of prevention of metal to metal contact by means of an intervening layer of fluid or fluid like material is termed as Lubrication

Functions of Lubricants

It acts as a thermal barrier and reduces friction and wear and prevents welded joints

Avoids seizure of moving surfaces

Acts as coolant

Acts as a seal and prevents entry of dust, moisture, & dirt between moving parts

Some lubricants acts as corrosion inhibitors thus reduce operational cost

Classification:

Three Different types of classifications are done

Based on occurrence / Source

Based on lubricant Physical State

Based on Lubrication process

Liquid lubricant examples:

1. Animal oils - Lard oil, Tallow oil, Whale oil

2. Vegetable oil - Castor oil, Palm oil, Coconut oil

3. Mineral based - Petroleum fractions

4. Emulsions

O/ W Cutting liquids

W / O Cooling liquids

5. Synthetic oils – blended mineral oils

Thick Film / Fluid film / Hydrodynamic Lubrication

In this type a continuous fluid film exists between the sliding surfaces

Employed when the sliding velocity is moderate and load is low

Used for machineries operated continuously

In fluid film lubrication, the fluid immediately adjacent to each surface travels at the same speed and direction of each surface.

Film thickness is ≥1000º A

Factors which affect the thickness of hydrodynamic fluid film include lubricant viscosity, rotation speed or RPM, oil supply pressure, and component loading.

An increase in speed or viscosity increases oil film thickness.

An increase in load decreases oil film thickness.

Coefficient of friction is 0.001 to 0.03 cm/sec

Blended Mineral oils are used to introduce a thick film between sliding surfaces

Finds application in watches, clocks and scientific instrument (stop watches)

Hydrodynamic lubrication often occurs in components such as cylinders, gears, and plain bearings

Boundary Lubrication / Thin film

Boundary lubrication often occurs during the startup and shutdown of equipment, or when loading becomes excessive.

Low speed , high load & non continuous operation

Thickness is 20 – 30 A

Coefficient of friction is 0.05 – 0.15 cm /sec

Film formation by either Physisorption or chemisorption

Oiliness should be high

Fatty acids and their soaps are used as additives

Used in automobiles and heavy machinery

Certain types of gear sets that need to withstand sliding pressures and shock loading, such as hypoid gears use boundary lubricants

| |

a and b – Thick film lubrication

c and d - Thin film lubrication

Extreme Pressure Lubricants

Extreme pressure lubricants interact with metal surfaces in a chemical process, at molecular level, to create a protective compound which increases the thermal stability of metal surfaces.

This is not a film or coating over the metal. It is a permanent modification of the metal surface

Molecules in the extreme pressure lubricants are polarized and actually bond with the metal surface

It is applicable in High load and high speed condition

Metal surface should be active (Fe, Cu etc.,)

Lubricants containing Chlorinated ester/ Sulphurised oils / Tricresyl phosphate are used

Surface compounds is formed due to chemisorption (ex.sulphurised oil containing lubricants reacts with Iron and forms Iron sulphide whose thermal stability is better than mere iron)

The thickness of the surface compound is a few molecule layer

Co. efficient of friction 0.1 – 0.4 cm /sec

It finds application in Air crafts and space crafts

Unique character of this type of lubricants is its replenish ability / easy of replacement

Extreme pressure lubricant

Important Properties

1. Viscosity and Viscosity Index

Viscosity is defined as Resistance to flow

Viscosity Index is the measure of resistance to change in viscosity

Viscosity Index (V.I) is value representing the degree for which the oil viscosity changes with temperature.

If change in viscosity ( ie decrease in viscosity with increase in temperature) is small , the oil is said to have a high viscosity index.

Low viscosity does not mean Low VI (Ex. Viscosity of water is less but VI of water is high)

Viscosity Index is measured using Red wood (Common Wealth Countries)

Viscosity Index is measured using Say bolt viscometer (USA)

Viscosity Index is measured using Engler viscometer (European countries)

Naphthalenic base Gulf oils have Low viscosity index (VI =0 , L series oils)

Paraffinic base Pennsylvanian oils have high viscosity index (VI =100, H series oils)

The viscosity of test oil is measured at 100o F and 210 o F

An oil possessing the same viscosity as that of test oil at 210 o F

is chosen from both L and H series

Their corresponding viscosities at 100 o F is noted from the series ( L and H)

If the viscosity of the test oil at 100 o F is considered as U then its VI can be calculated using the formula

V.I. = (L – U / L – H) x 100

Polymers and copolymers of olefins, methacrylates, dienes or alkylated styrenes are used as viscosity index improvers

When the oil gets heated up due to frictional heat, the viscosity of the oil decreases.

The solubility of a polymeric molecule increases with increase in temperature which results in the increase in viscosity

Hence at elevated temperatures, the decrease in the viscosity of the oil will be balanced by the solubility of the polymer in oil. Thus polymers act as good VI improvers

Good motor oil has a high V.I.

2. Tackiness / oiliness / lubricity

Oiliness is defined as the ability of the oil to stick firmly to a solid surface

Oiliness should be high for a good lubricant

Can be improved using additives – long chain fatty acids and soaps are generally used as tackiness improvers

Very essential in Boundary lubrication as tackiness improves replenish ability of the surface film

3. Cloud and Pour Points

Cloud point is defined as the minimum temperature at which oil becomes hazy

Pour point is defined as the minimum temperature at which oil stops pouring( or ceases to flow)

When oil is cooled , wax starts crystallizing , and the oil becomes hazy

Tiny wax crystals agglomerate and form bigger crystal lattice, at this stage the oil solidifies completely and does not pour out on tilting.

Both cloud and Pour points should be very less than the operating temperature

Cloud and pour points can be reduced by adding depressants

Polymeric additives such as poly amino alcohols are added to decrease cloud and pour points

Other pour point depressants include alkylated naphthalene’s and phoenolic polymers, poly methacrylates, maleata/fumarate and copolymer esters

The additives lower the pour point either by forming a thin coating over wax and prevent it from agglomerisation or co precipitate along with wax , thus reducing the freezing point

(For diagram, description and working of cloud and pour point apparatus refer Text book - 194 OR class notes)

4. Flash and fire Points

Flash point is defined as the lowest temperature at which the oil gives off just enough vapours which gives out a flash when an open (tiny ) flame is brought near the vapours

Fire point is the lowest temperature at which the oil gives off enough vapours which burns continuously at least for 5 seconds

Flash and Fire points should be high for a good lubricant

Flash and fire point additives are used to increase the performance of a lubricant

CTFE is added to increase flash and fire points as it increases the vaporization point of lubricants

Usually there is a difference of 5 – 40o C between both for a good lubricant

Blended oils

Practically no single lubricant will be able to satisfy all the properties of a good lubricant. Hence it is essential to add various additives to achieve the required performance.

The process of adding different substances to impart a special character to the base oil is called blending and the resulting oil is called blended oil.

The following table gives the various additives and their function in synthetic oils / blended oils

| Name of the additive | Substance added to lubricating oils | Function |

| Oiliness | Fatty acids like stearic acid, palmitic acid, oleic acid Vegetable oils | Increases lubricity Prevent rupture of film |

| Extreme Pressure additives | Organic chlorine compounds / organic sulphur compounds / phosphorous compounds | Form surface compounds which has better thermal stability & wear resistance |

| Viscosity Index improvers | n-hexanol, polyalkyl benzene, polyisobutylene | Reduce the rate of change of viscosity with Temperature |

| Pour point depressants | Phenols, chlorinated hydrocarbons | Prevent the agglomerisation of wax which separates out from the lubricating oils |

| Thickeners | Polystyrene, polyesters | Increase the viscosity of lubricating oils |

| Antioxidants | Phenolic compds, aromatic amines | Prevent oxidation of oil. Prevent gum formation |

| Deposit inhibitors / detergents/ deflocculents | Salts of carboxylic acid / salts of phenols/ sulphonates | Reduce deposits in engines which block the passage of oil |

| Corrosion inhibitors | Organic compounds of Phosphorous / antimony | Get adsorbed on metal surface and protect the surface from attack by moisture |

Solid lubricants

Solid lubricants are deposited in the valleys to create a smoother surface.

They are designed to protect against metal contact by coming between two peaks at the moment of contact.

This results in the deformation of the peak, rather than formation of welded joints.

Even between highly loaded stationary surfaces the lamellar structure is able to prevent contact.

Large lubricant particles perform better on relative rough surfaces and at low speed, while finer particle perform better on smooth surface and higher speeds

(1st and 2nd are sliding surfaces and 3rd is solid lubricant filling the valley)

Layered Compounds like graphite , boron nitride ,molybdenum di sulphide , talc , teflon, mica, calcium fluoride , cerium fluoride, tungsten disulfide etc are as solid lubricants used

Graphite (organic substance) and molybdenum disulfide (MoS2 is inorganic substance) are the predominant materials used as solid lubricant due to their lamellar structure

The lamellas orient parallel to the surface in the direction of motion and shears over each other easily, resulting in a low friction.

Graphite

Graphite is a form of carbon which exists as a stack of 'sheets' of carbon atoms, each sheet having a hexagonal arrangement of atoms

Three valencies are satisfied by covalent bonds and the fourth is weak Vander

Waals Force

Both crystalline and amorphous form of graphite find application as lubricant, however amorphous graphite does not possess high shear strength hence used only when load is low.

Both natural and synthetic graphite can be used as lubricants

Graphite is soapy to touch and non inflammable

The C-C bond length is 1.42A and the distance between two hexagonal planes is

3.4A

It is stable up to 375oC (in presence of air)

Water vapor is a necessary component for graphite lubrication.

The adsorption of water reduces the bonding energy between the hexagonal planes of the graphite

Because water vapor is a requirement for lubrication, graphite is not effective in vacuum

Graphite is usually mixed with oil / water/ greases

Graphite mixed with oil is called oil dag and graphite mixed with water is called aqua dag

It is used to lubricate air compressors , railway track joints , food stuff industries , IC engines etc.,

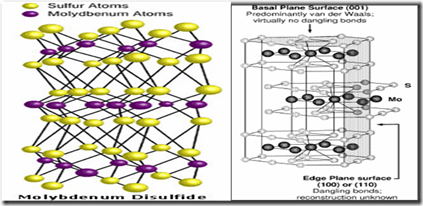

Molybdenum di Sulphide

Just like graphite, MoS2 also has a hexagonal crystal structure with the intrinsic property of easy shear

MoS2 lubrication performance often exceeds that of graphite and is effective in vacuum also

Mo layer is sandwiched between two sulphur layers

Like graphite it has weak van der Waals forces between the basal planes.

The bonds between the sulfur layers are weaker than the bonds between the molybdenum layers.

The Metallic bond length , Mo-Mo is 3.08A , the covalent bond length S-S is

3.15 A and the distance between two lamellas is 3.13A

It is stable up to 425oC in presence of air and up to 800oC in absence of air

It is chemically inert

It may be used in the form of powder/ mixed with oil or greases

Water is not essential for its lubricity hence can be used in vacuum too in fact its lubricity decreases in presence of water

It is used in IC engines.

I agree with a lot of the points you made in this article. If you are looking for the Lubricants Dealers In Erode, then visit Mavani Synthetic Lubricants (P) Ltd. I love your content, they are very nice and very useful to us and this text is worth everyone’s attention.

ReplyDeleteGood post. I certainly love this website.

ReplyDeleteContinue the good work!

mini goldendoodle for sale

mini bernedoodle puppies for sale

mini aussiedoodles for sale

ragdoll cat for sale

ragdoll cats for sale

teacup havanese puppies for sale

great dane puppies for sale

great dane puppy for sale

great dane puppies near me

Hi, I do believe this is a great website. I stumbledupon it ;) I am going to revisit yet

ReplyDeleteagain since I book-marked it. Money and freedom is the greatest way to

change, may you be rich and continue to help other people.

great dane puppy for sale

great dane puppies for sale near me

goldendoodle for sale

ragdoll kitten near me

ragdoll kittens for sale near me

bernedoodles for sale

aussiedoodle for sale

havanese puppies for sale near me

Royalcasino310

ReplyDelete